Optical Bonding Facilities

To ensure consistent and stable quality, Data Image operates its own in-house optical bonding production line. Optical bonding improves LCD readability and durability, supporting reliable performance in industrial and outdoor environments. With controlled internal processes and validation, we can recommend the right bonding approach for different use cases—while maintaining high quality across a wide range of panels and project requirements.

Improved readability in sunlight

Reduce reflection

Enhance Ruggedness and durability

Prevents condensation or fog on the display

Core Technology

Optical Bonding

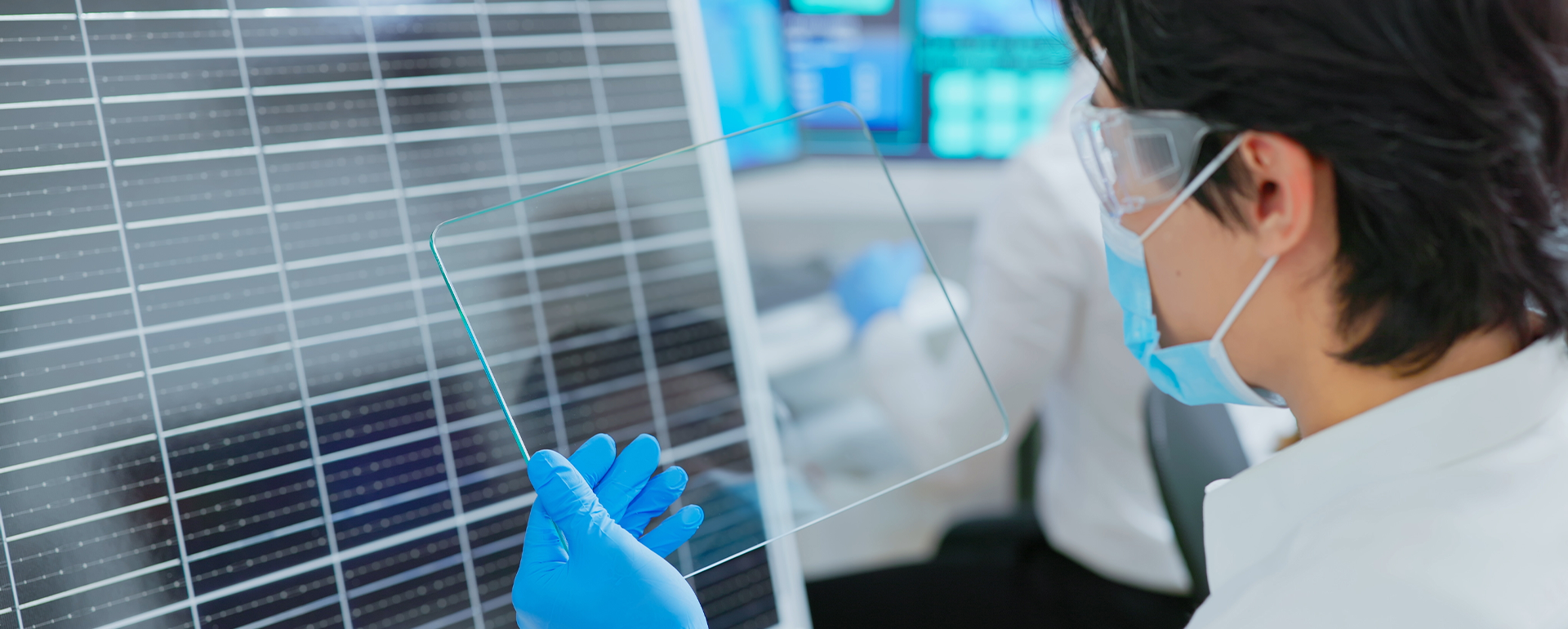

Optical bonding can be implemented with different processes and materials—such as silicone, polyurethane, epoxy, and acrylic-based adhesives—selected based on the product structure and application needs. These bonding materials are typically cured through controlled mixing and curing conditions, including heat curing or UV curing. Depending on the design and production requirements, bonding can be performed as wet bonding (LOCA) using a liquid adhesive, or as dry bonding (OCA) using a pre-formed optically clear adhesive film.

As with any adhesive process, material selection directly impacts long-term durability, and strong adhesion and compatibility with the component surfaces are equally critical. To ensure consistent bonding quality, we apply dedicated surface preparation before bonding, including a two-stage pre-treatment process to improve adhesion performance and overall reliability. This approach helps stabilize the bonding process—even on more challenging surfaces—resulting in stronger, more reliable bonding outcomes.

Dry Bonding

In dry bonding, the bonding material is cut to the size of the visible display surface and the air gap is filled homogeneously with it. There is a choice of several bonding materials in different thicknesses and consistencies, which are selected on the basis of the displays and the specifications of the application. Displays have different heights of metal frames depending on the model and diagonal. The optimum material thickness is determined on the basis of the displays. The front glass with touch and display are joined together under vacuum in the bonding machine.

Wet Bonding

Unlike most displays, those used in automotive, marine interiors endure harsh environmental conditions, including extreme temperatures, high humidity, and prolonged UV exposure. They consequently demand more robust adhesive materials that still support simple, cost-effective processing.

OCA

OCA is a simpler, faster and more cost-effective process, still offering good durability and readability.

By applying this process, the air gap is eliminated and therefor the reflective index is reduced and brightness of the display increased, resulting in enhanced visibility.

OCR

OCR is the most durable of these methods, able to best withstand impact, shock and vibration. It offers the best readability, especially in sunlight, since it is best at eliminating internal reflections.

Which optical bonding process is suitable?

The optical bonding process and adhesive selection depend on the display’s operating environment and use case. Based on the application details you provide—such as outdoor/industrial conditions, mechanical constraints, and reliability targets—we evaluate and recommend the most suitable bonding approach, delivering a cost-effective solution without compromising performance or durability.

Increase product durability and performance

With robust processes and reliability-focused design, our display components are built to withstand demanding environments, including:.High altitude and pressure changes

.Extended operating temperature ranges

.Severe shock and vibration

.Condensation and moisture exposure

In addition, optical bonding eliminates air gaps between bonded interfaces, helping reduce the risk of internal condensation and improving long-term reliability in outdoor and high-humidity deployments.

More Technology

.png)