Professional Display

Take your design to the next level with our range of TFT displays, including the latest IPS TFTs in circular, bar-shaped, and large sizes. Whether you prefer what kind of sharps, these displays are fully customizable to meet your system requirements.

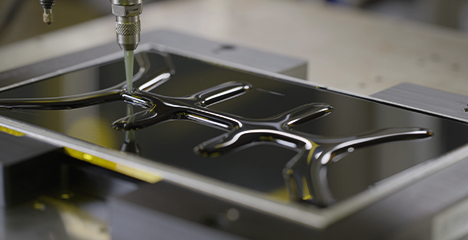

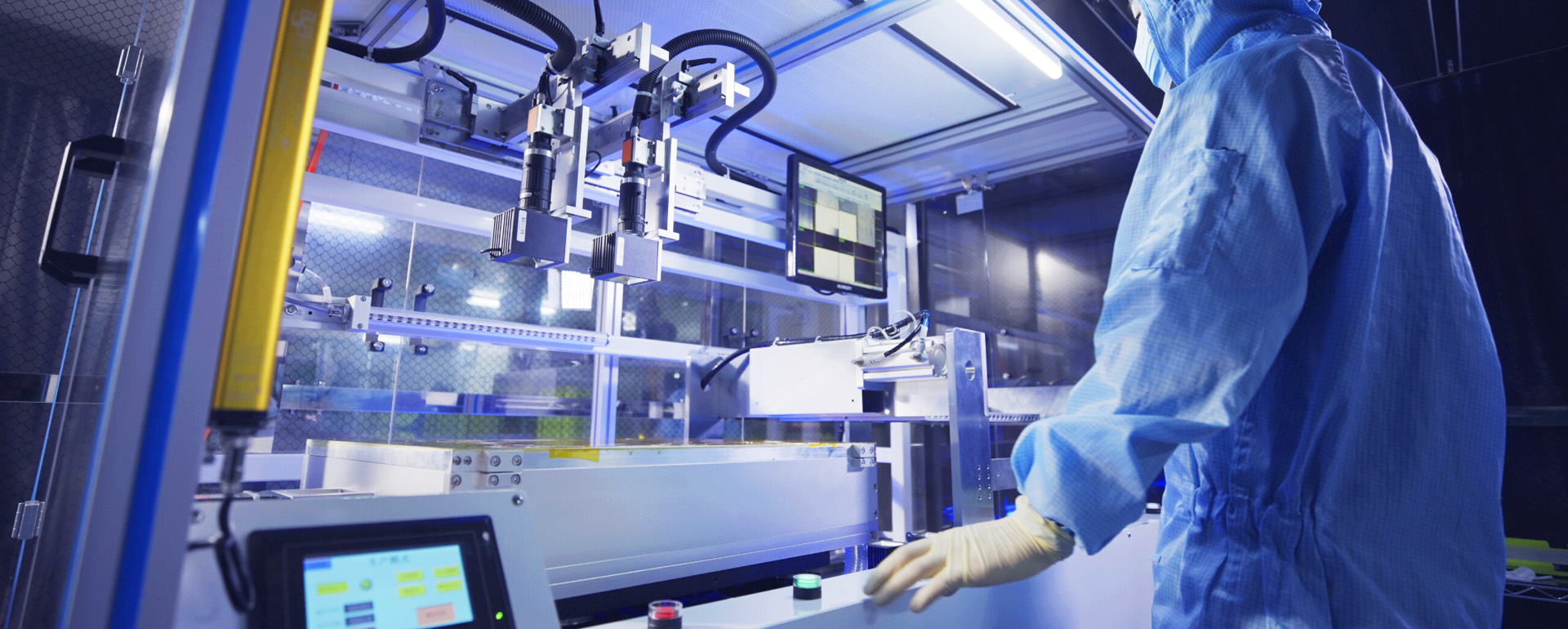

Core Technology

We Generate Technical Solutions

Data Image is creating innovative user experiences based on touch technology. We are experts at innovating and finding suitable solutions for all challenges, We offer both optical bond and tape adhesion methods, as well as harsh environment enhancements like chemically strengthened glass and EMI shielding.

Durability Displays

Our rugged displays are environmentally sealed to IP65 ratings for applications where dirt, dust, moisture and water are present. Reliable, Rugged and Durable!

Circular Displays

An all-new and unique round infotainment screen screams classic gauge design. Our circular displays are available from 1" to 4.2" and a great solution to give your product design a modern feel.

Heavy Outdoor Displays

With a wide range of sizes including 4.3” to 27”, we offer glassbridge, waterproof, high-bright, sunlight readable and pilothouse options that perform flawlessly in all-weather and environmental conditions.

Stretched Displays

The multifunction display, a compact information unit, is positioned directly in front of you on the dashboard for your convenience and safety. It lets you see important information at a glance, without taking your attention from the road.

Round Displays

Rotary selection is ideal for intuitve adjustments such as temperature control, volume, motor speed, timer settings, lighting, dimming and ambience settings.

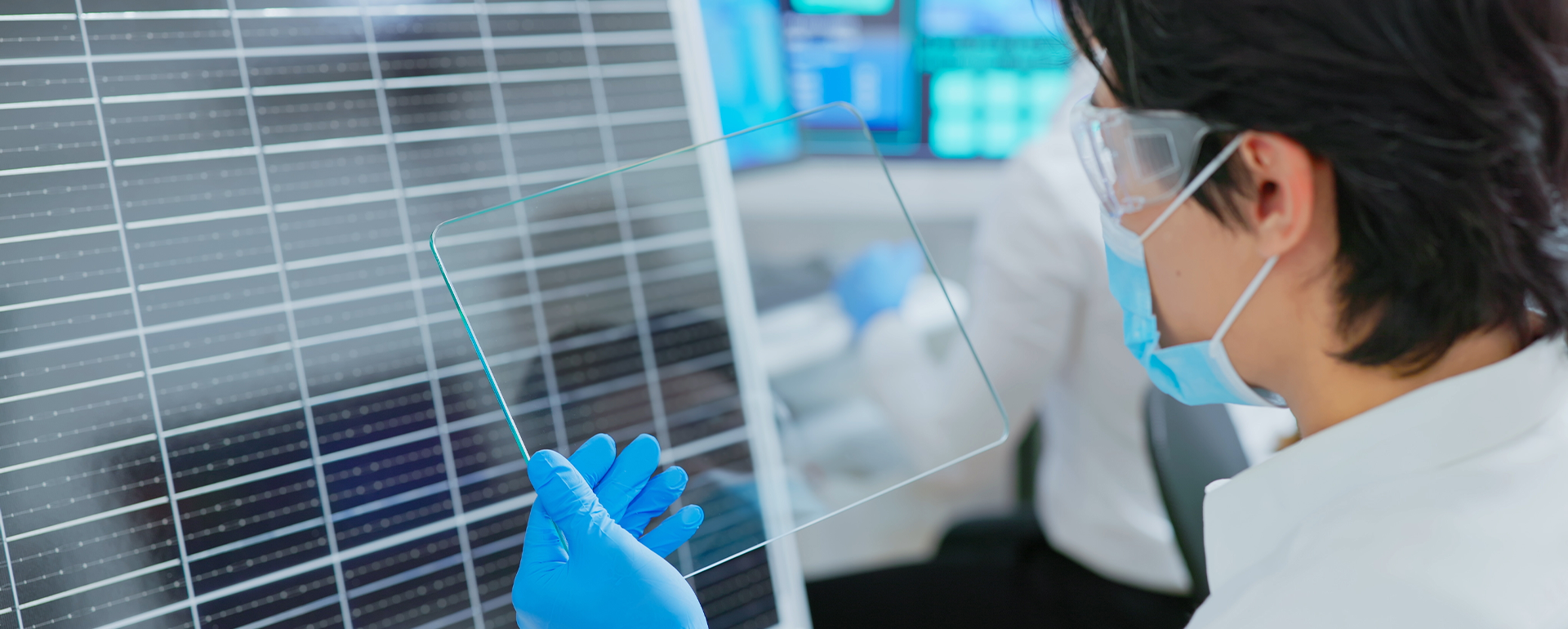

Ultra Wide Displays

Advanced stretched panel is ideal for information display. Native photo mask manufacturing process ensure high quality and outstanding performance. 32:9 ratio from get-go. Available in a variety of sizes and configurations. Can be utilized in different applications.

More Technology

.png)